PHE (PLATE HEAT EXCHANGER) SUBCOOLING

Plate Heat Exchanger as a secondary intercooler boosts up refrigerant subcooling and improves 10% energy efficiency.

HIGH SEER AND SCOP VALUES

EMS (Energy Management System)

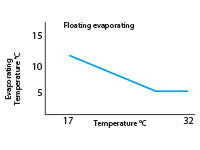

Floating refrigerant temperature for balancing comfort and efficiency

The evaporating temperature (in cooling) and condensing temperature (in heating) are automatically adjusted according to both indoor and outdoor temperature to maximize the comfort and energy efficiency.

Capacity output limitation for shortage of electricity

With the integration of EMS, for projects with limited electricity supply, MV6 can be set to output 40-100% capacity.

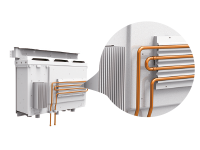

PHE (PLATE HEAT EXCHANGER) SUBCOOLING

Plate Heat Exchanger as a secondary intercooler boosts up refrigerant subcooling and improves 10% energy efficiency.

HIGH SEER AND SCOP VALUES

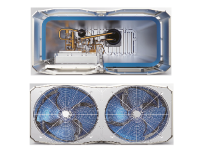

HIGH EFFICIENCY G-TYPE HEAT EXCHANGER

24-32HP units use high efficiency 3-rows G-type heat exchanger which heat exchange area is 1,5 times than 22HP unit. The 24-32HP units also use super big size fan which diameter is up to 750mm.

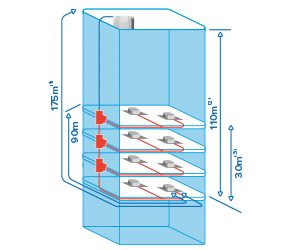

- WIDE CAPACITY RANGE

The whole lineup of VRF MV6 is from 8HP to 96HP in 2HP increasement with the world’s largest single refrigerant system capacity up to 96HP.

- ANTI-CORROSION PROTECTION

Outdoor units are given anti-corrosion treatment for non-extreme conditions as standard and can also be customized with heavy anticorrosion treatment on main components for surface protection against corrosive air, acid rain and saline air (for installations in coastal regions) to extend overall useful life. The integrity of the anti-corrosion treatment is ensured by subjecting major components and parts to salt mist testing, moisture and heating testing and light aging testing.

- AUTO SNOW-BLOWING FUNCTION

The innovatively designed auto snow-blowing function enables the outdoor unit to prevent the accumulation of snow by itself.

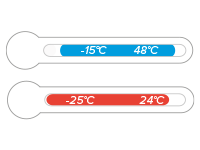

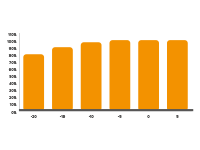

WIDE OPERATION RANGE

VRF MV6 can operate in a wide ambient temperature range.

It can operate stably from -15°C up to 48°C in cooling mode and from -25°C to 24°C in heating mode

LONG PIPING CAPABILITY

High Reliability

- PRECISE OIL CONTROL TECHNOLOGY

Four stages of oil control technology ensure all outdoor compressor oil is always kept at a safe level, eliminating any compressor oil shortage problems.

- Compressor internal oil separation.

- High-efficiency centrifugal oil separator (with separation efficiency of up to 99%) ensures that oil is separated from the discharge gas and returned to the compressors in a timely fashion.

- (Oil balance pipes between compressors ensure even oil distribution to keep compressors running normally.

- Auto oil return program monitors the running time and system status to ensure reliable oil return.

- DUTY CYCLING

Duty cycling equalizes the running time of the outdoor units in a multiple-unit system and of the compressors in each unit, significantly extending compressor lifespan.

- BACKUP OPERATION

In one unit with two compressors, if one compressor is failed, the other compressor can be backup instead of the failed one to maintain up to 4 days interim capacity, allowing time for maintenance or repair while comfort remains guaranteed.

In a multi-unit system, if one module fails, the other modules provide backup so that the system can continue operating.

- DUST-CLEAN FUNCTION

The innovatively designed dust-clean function enables the outdoor unit to prevent the dust by itself.

REFRIGERANT COOLING PCB

The MV6 series uses refrigerant cooling technology to cool the electric control box. It decreases the average temperature of electrical control components by about 8 degrees, guaranteeing the stable and safe running of the control system.

Enhanced Comfort

- NIGHT SILENT MODE

The night silent mode feature includes various scheduling options that can be used to reduce noise levels when low noise operation is required: only during night hours or continuously, and with different noise reductions levels limiting only maximum fan speed or compressor speed also.

- INTELLIGENT DEFROSTING TECHNOLOGY

The intelligent defrosting program calculates the time required for defrosting according to the actual system status, eliminating heat losses from unnecessary defrosting. A specialized defrosting valve reduces time required for defrosting to as little at four minutes.

- MULTIPLE PRIORITY MODE SETTINGS AVAILABLE

Operating mode priority can be set among different modes (automatic, cooling priority, VIP indoor unit, heating only, cooling only) to satisfy every specific user's need. Setting can be performed on outdoor unit directly or by centralized controller.

ENHANCED HEATING CAPACITY

Thanks to the vapour injection DC Inverter compressors, heating capacity can achieve 100% output when the ambient temperature is down to -5°C and 90% output when ambient temperature is down to -15°C.

Easy Installation and Service

- AUTO ADDRESSING

Outdoor unit can distribute addresses to indoor units automatically.

Remote and wired controllers can be used to query or modify each indoor unit’s address.

- AUTOMATIC REFRIGERANT CHARGING FUNCTION

Automatic refrigerant charging function make the installation and service easier and more efficient, automatically collecting refrigerant from the tank and stopping the operation when exact refrigerant charge is done.

- SMART INPUT/OUTPUT CONTACTS

Convenient connectors are available as standard on unit PCB, to realize some convenient operations on field with other building appliances depending on users’ needs. Available contacts are heating/cooling switch as input and alarm as output

This website uses cookies, including third party ones, to enable website operations, for statistics, to improve your navigation experience and personalise the communications sent to you. You may accept these cookies by clinking on “Accept all” or clicking on “Preferences" to personalise your choices. On closing the banner without accepting, the website will only use technical cookies (needed for the website to operate).

For more information, even on single cookies, please read our cookie policy and our privacy circular.

United Arab Emirates

United Arab Emirates  +971 (0) 4501 5840

+971 (0) 4501 5840  info@clivet.ae

info@clivet.ae  France

France  Germany

Germany  +49 40 325957-190

+49 40 325957-190  United Kingdom

United Kingdom  India

India  Russia

Russia  South East Europe

South East Europe